Ruwac Asia Blog

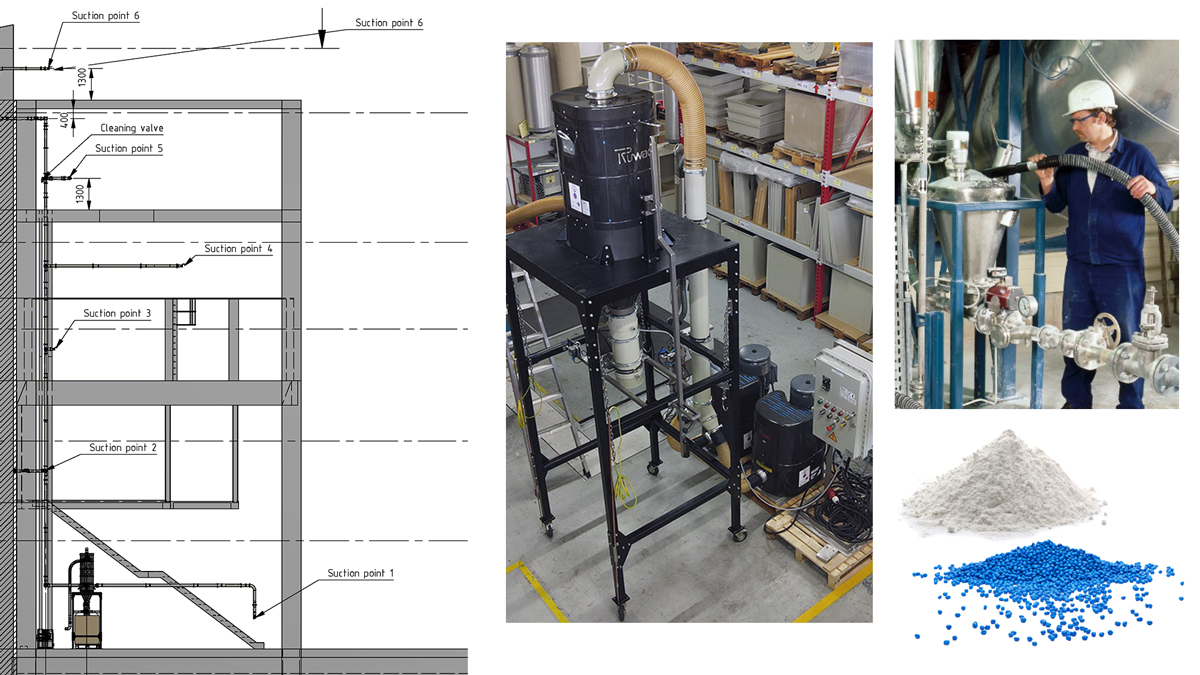

Central Vacuum System for Pelletizer Building Floor Cleaning

- July 21, 2021

- Success Stories

Central Vacuum System for Pelletizer Building Floor Cleaning

PTT Global Chemical Public Company Limited, Thailand 2021

To Vacuum clean working area around Pelletizer building which is 4 levels 20m high at different working areas to ensure safe collection of dangerous material and protect the workers and enforce good housekeeping.

RUWAC SOLUTION:

- DS2720 3 Phase ATEX Zone 1+2+21 II 2 D/G

- D2 Silo Stand frame for big bag collection of the vacuum material

- Additional Grounding for Silo and Big Bag

- Throttle valve with pneumatic rotary actuator for collection of material in big bag

- JACOB Powder coated steel piping

- Remote Start / Stop control box at each suction points

- Alarm for filter cleaning after each operation

TECHNICS:

- 2 x DS 2720 drive unit 7.5kw – Zone 1+2+21 II 2D/G

- Silo pre-separator system with filter 4.5m2

- Customized silo stand frame for big bag

- Accessories DN50mm with accessories holder

- Jacob piping system DN100mm made of Powder coated steel

- 6 Suction points operated only a maximum of 2 suction points at a time!

- Manual shaking extension device for handshaking filter cleaning

- Endcap on each floor

- Control cabinet with digital text display shows status and malfunction

- Remote start/stop by selector switch on each suction point

- Continuous discharge with 2 x pneumatic valves open / close sequence adjustable timing.

- Automatic piping cleaning valve function after stop operation.

- Turbine temperature switch 112 C

- Alarm timer to inform the operator to manually carry out filter shaking process – Filter differential pressure monitoring max 80mbar

- Max vacuum pressure monitoring function

ADVANTAGES:

- Workers are now better protected from exposure to harmful dust in working area.

- Cleaning is efficient and safe and dust clouds are no longer formed by sweeping.

- Cleaning time is greatly reduced with the easy use of accessories and hose at different suction points around the Palletizer building.

- Easy access to a Vacuum solution to clean any spillage or dust on the floor.

- Safety concerns such slip and falls are reduced due to cleaner floors.

- Dangerous material is safely stored for easy disposal when full.

- Workers no longer need to frequently touch or change filters.

- Workers spend approximately 30 mins after each shift to clean work area compared to previous 2 hours, saving 75% of the time spend

- Only 2 Workers required for cleaning, saving 50% of manpower.

- Production time has been greatly improved.

Success stories link please click here

Industries Chemical Plastic Compounds Polymers Application Floor Cleaning Application Category Vacuum cleaning of surfaces Suction Media Calcium, Zinc Stearate and Phenol