Ruwac Asia Blog

Concrete Dust Suction system for prefabricated houses production plant

- February 1, 2018

- Cement Plant, Chemical Industry, Dedusting at source, News, Success Stories

In the production of seasoning powders any different ingredients are used, all having different properties. A detailed analysis is necessary in order to provide different customizing options to solve the different dust specification challenges. Dust extraction with flexible extraction arms directly at mixer charging stations where fly dust contaminates the area. Installing a certified dust extraction system with high efficient filtration and dust collection capability. The RUWAC Dust Extractor DS 6 serves as a dust collector that can be customized for standalone operation, as a mobile extractor or as a central dust extraction system/ dust collection system for many extraction points. Due to the modular design the dust load on each filter unit is equally distributed across the available filter surface. Various dust collection and filter cleaning options for prolonged continuous operation are also available.

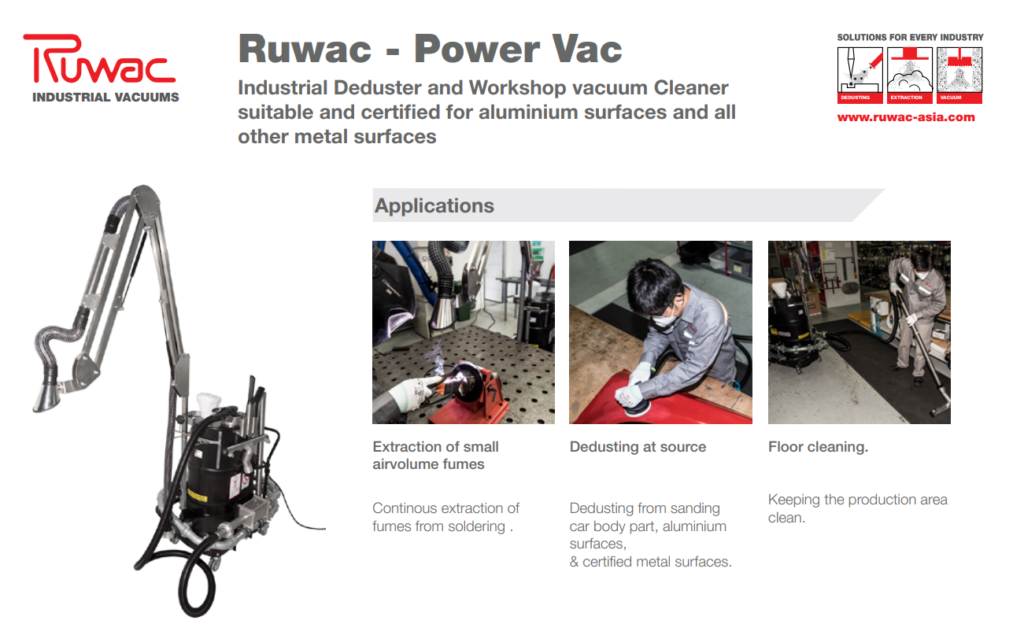

| Industries | – Construction – Metal Working – Original Equipment Manufacturer |

| Application | Suction from hand sander |

| Application Category | Dedusting at source |

| Suction Media | – Cement dust – Cement fine dust |

| Reason | Protect workers from dangerous dust concentration at work place / Dust control to comply with local regulations / Reduce dust contamination of product |

| Product Group | Mobile Vacuums |

| Sparks | Yes |

| Task | To reduce the airborne cement dust amount within the production area

To protect operators from inhalation of cement dust |

| Problem | 1.Hand grinding tools in use without dust suction. 2.Easy to use solution with large capacity dust collection at grinder not available in local market 3.Operation must be same as before and grinding tool must not be too heavy to hold 4.Adapting Solution to fit the Operators working style |

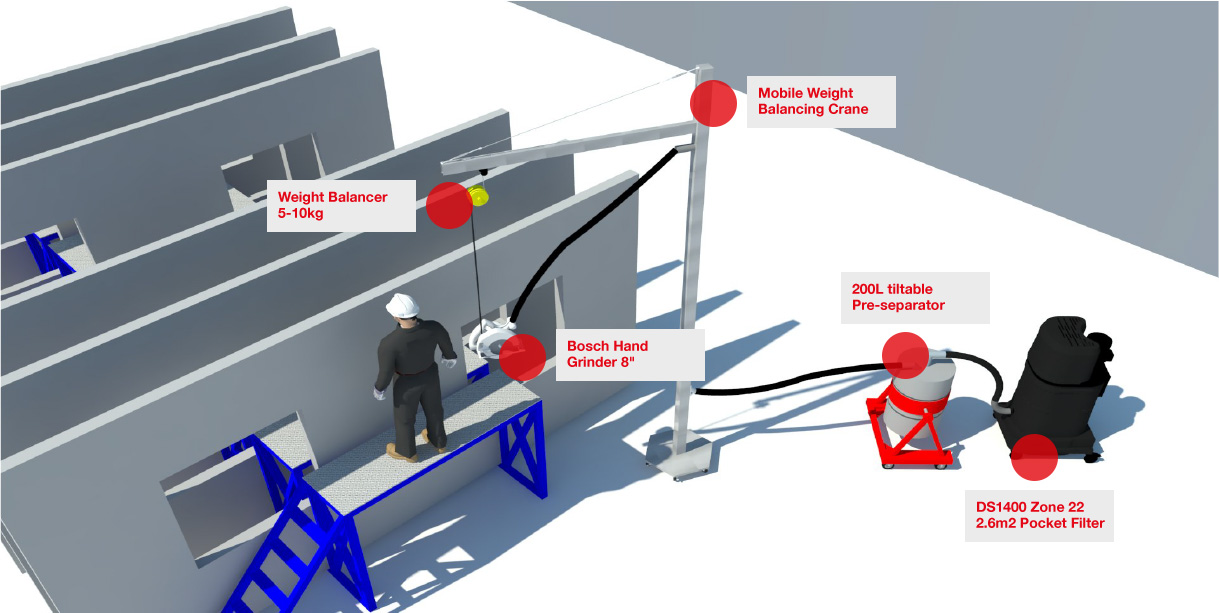

| Solution | DS1400 4.0kw 2.6m2 Pocket Filter Zone 22 + 200L Pre-separator, Accessory Pack V, Bosch Hand Grinder Suction Hood, Bosch Hand Polisher Suction Hood, Weight Balancing Crane for Hand Grinder & Polisher |

| Technics | Since Sparks are present during the Grinding process, the 200L Pre-separator is needed to slow down the cement dust mixed with the sparks to extinguish the sparks.

Cement Dust works as an extinguishment material within the 200L Pre-separator; no spark trap or wet-separator required. |

| Advantages | 1.80 % reduction in overall dust amount within the production area by direct dedusting from grinder 2.Reducing the dust exposure to the operator to below government regulation limit of allowed dust concentration at work place 3.Convenient operation of hand held grinder tool with weight balancing crane solution 4.Reduce operation time through efficient working equipment |

Read more about the related “Application Packages”