Ruwac Asia Blog

RUWAC Asia sales and service training seminar 2018

- December 13, 2018

- News

RUWAC Asia sales teams from Thailand, Korea,China,Malaysia and Indonesia came together at Ruwac regional training center and production plant in Chonburi,Thailand. (11-15 Dec 2018) Topic: Market research – Industries Lead A, Prospect, Conversion, Contact, Company, Customer Inquiry types, Project, Quotation types, Typical inquiry clarification cases Detailed product program structure Base Model, Customizing,Options,Accessories,Piping,Wear Parts,Consumables,Spare Parts,Service Quotation, Solutions – Applications – Success Stories Piping – Losses – Isometrics – Central Systems – Basic Know How Working Point and Testing – Performance Curve – Test machines and Testing tools ATEX – Explosion prevention …

RUWAC S24D Vacuum Truck at Holcim Philippines Inc

- October 29, 2018

- S24D Vacuum Truck, Success Stories

A team of subcontractors was utilized to collect massive amounts of cement powder from the ground by sweeping and shoveling. This results in a very costly, inefficient and time consuming solution in both short and long run. RUWAC have introduce the solution S24D Vacuum Unit + Round Tank Vacuum Truck to reduce labor intensive work in removing massive amounts of cement powder in various production lines and to be able to vacuum massive amounts of cement powder in various production lines and narrow areas. Ruwac S24D Vacuum Truck, 100kW (136HP) Deutz Diesel …

Handover of the S24D vacuum to Holcim Philippines Inc

- October 29, 2018

- News, Picture of the week

Holcim Philippines Inc. received a S24D Vacuum Truck on 11/10/2018. The S24D vacuum unit is equipped with a 100kW Deutz Diesel engine connected to a round 10m3 carbon steel container which is mounted onto a 6 wheeler truck. The purpose of this vacuum truck is to vacuum massive amounts of cement powders in various production areas in a short amount of time and reduce overall manpower for cleaning. Mr. Gerardo “Gerry” Dela Cruz Jr. (4th from the left), Project Supervisor says that our Ruwac S24D vacuum truck has decreased their …

Handover of the DS1400 mobile vacuum at Markenburg International Foods Corporation Philippines

- October 29, 2018

- News, Picture of the week

Markenburg International Foods Corporation Philippines received a DS1400 Vacuum System ATEX Zone 22 on 28/09/2018. The DS1400 mobile vacuum unit is combined with a 110L Pre-Separator System with bag suction. The purpose of this vacuum unit is to generally clean corn starch powder in the marshmallow production line and replacing the wet cleaning process. Mr. Alfred de Guzman (Middle), Plant Manager says that our Ruwac vacuum system has decreased their cleaning time of the production area, increased cleaning efficiency & helped his operators from being exposed to corn starch powders.

Handover of the The DS65600 Extractor System at Markenburg International Foods Corporation Philippines

- October 29, 2018

- News, Picture of the week

Markenburg International Foods Corporation Philippines received a DS65600 Extractor System ATEX Zone 22 on 28/09/2018. The DS65600 Extractor System is combined with a DN800 High Speed Cyclone System with level sensor. The purpose of this vacuum unit is to extract airborne corn starch powder in the marshmallow production line during charging and sifting process. Mr. Alfred de Guzman (Top, Middle), Plant Manager says that our Ruwac vacuum system has reduced the overwhelming corn starch dust cloud during production process & helped his operators from being exposed to airborne corn starch powders.

DS65600M Extractor System for Markenburg International Foods Corporation

- October 29, 2018

- DS65600M Extractor System

The previous dust collector solution does not have enough airflow to collect the dust cloud at Markenburg International Foods Corporation. They need the solution to reduce corn starch dust cloud during manual charging process into coating hopper and extract airborne corn starch powder during manual charging process into coating hopper. RUWAC SOLUTION: DS65600M Extractor System + DN800 High Speed Cyclone, Ruwac Extractor System DS65600, 4.0kW 3-Phase Side Channel Blower, 55L dust bin capacity, ATEX Zone 22 II3D, 24m2 Cartridge Filter Class M, compressed air filter cleaning system through differential pressure sensor + DN800 …

DS1400M Mobile Industrial Vacuum for Markenburg International Foods Corporation

- October 29, 2018

- DS1400M Mobile Industrial Vacuum, Success Stories

Currently the wet cleaning procedure is very time consuming and is ineffective in its outcome, Markenburg International Foods Corporation need to speed up and improve cleaning process in marshmallow production line and generally clean corn starch from marshmallow production line floor and equipment. RUWAC Solution: RUWAC DS1400M mobile industrial vacuum unit + 110L Pre-separator with bag suction, mobile industrial vacuum cleaner DS1400M, 4.0kW 3-Phase Turbine Drive, 35L dust bin capacity with bag suction, ATEX Zone 22 II3D, 2.6m2 Pocket Filter Class M + 110L Pre-separator with bag suction, stainless steel ADVANTAGES: Faster and …

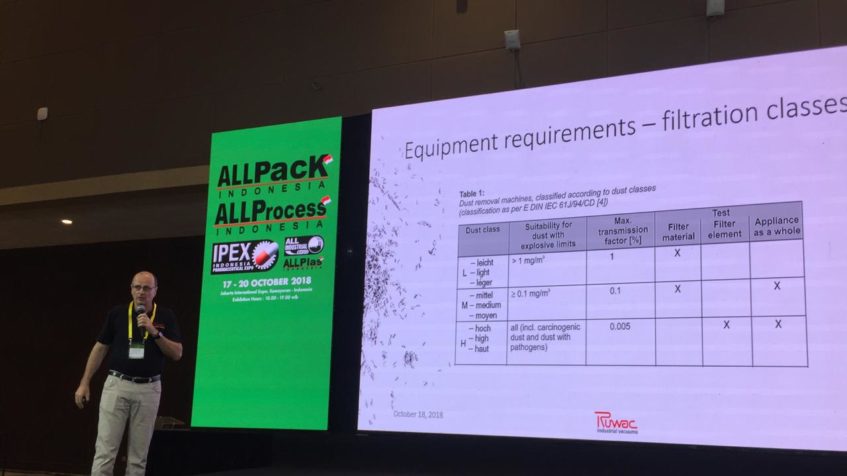

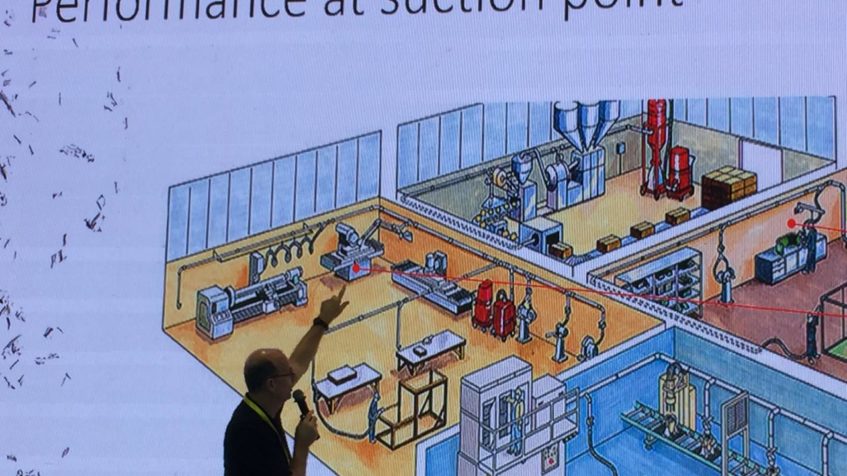

Ruwac Asia seminar at ALLPack expo Indonesia

Planning and selection of dust control equipment for food processing factories Thursday, 18 October 2018. 13.00 – 15.00. Venue: JIExpo, Kemayaran Hall C3. Speaker: Mr.Jens Huhn – Managing Director of Ruwac Asia Group Topic: Guideline for the setting up of a factory dust safety and hazard analysis document according to European and US regulations Requirements for dust control equipments according to GMP, ATEX regulations and European machinery norms Selection criteria for industrial vacuums and dust collectors Step by step planning guide for the implementation of a well performing, cost efficient and …