Ruwac Asia Blog

DS65600 Extractor System PGI Foods International Co.,Ltd., Thailand 2017

- March 5, 2018

- Chemical Industry, DS65600 Extractor System PGI Foods, Extraction of airborne dust, Extraction of dust from mixer, Food Industry, Success Stories

The DS64000 Extractor System with a 24m2 Cartridge Filter Class M is connected to 4 Suction Points whereas 2 suction points are operated at the same time. The purpose of this Extractor System is to extract airborne icing sugar powder from their mixer, filling station & sifting station. PGI Foods International Co.,Ltd. received a DS64000 Zone 22 Extractor System by Khun May (Right), Production Supervisor said that our RUWAC extractor system has decreased the dust cloud within the small production area, which resulted in a healthier more productive working environment. …

DS1750 Sludge Vacuum System 7.5kW Turbine Drive IRPC (Public) Co.,Ltd., Thailand 2017

- March 5, 2018

- DS1750 Sludge Vacuum System, Electronics, Engineering, Foundry, Machinery, Plastic, Power plant, Success Stories, Vacuum cleaning of floors and surfaces

IRPC operators used to clean this area by manually scooping up the heavy sludge on a monthly basis, which is a time consuming & physically demanding task to do the general Cleaning of waste polyethylene sludge with chemical liquids, oils & water. A DS1750 Sludge Vacuum with full automatic features has been implemented to clean sludge from 4x waste water pits on a weekly basis to reduce physical demand during cleaning task and safe time by reduce manpower from 5 operators to 2 operators. DS1750 7.5kW Turbine Drive, 2x 5m2 Oil …

DS1750 Silo Vacuum System Siam Kubota Metal Technology Co.,Ltd. Thailand 2017

- March 5, 2018

- Steel, Success Stories, Vacuum cleaning of floors and surfaces

Our customer Siam Kubota Metal Technology Co.,Ltd., Thailand have many steel shots by its nature have a very high specific weight making the material very heavy. By manually shoveling these steel shots, operator’s physical health is & operation downtime is effected. To reduce operation down time of collecting steel shots but Increase collection capacity to time ratio and also convenient discharge through bottom discharge valve into customer containers. The DS1750 Silo Vacuum System 7.5kW Turbine Drive, 4.5m2 Pocket Filter Class M, 160L Silo Container, manual heavy-duty bottom discharge valve is …

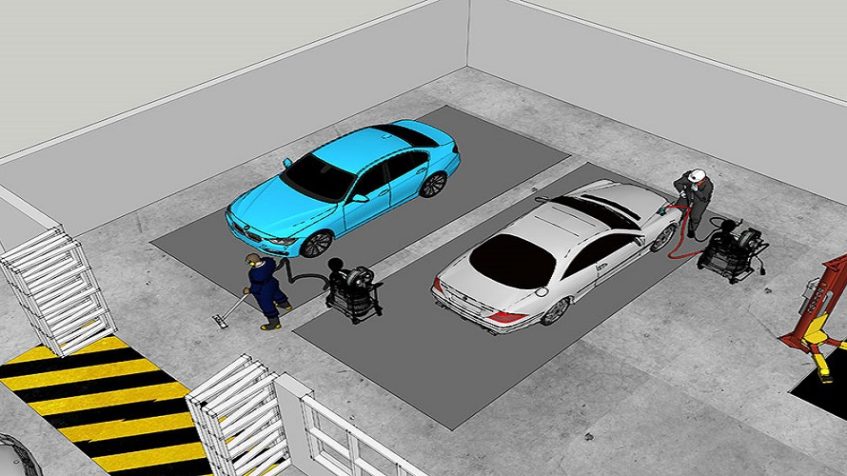

DS 1220 spark trap vacuum for aluminium car body sanding Autoland, Singapore 2016

- February 13, 2018

- Aerospace Industry, Automotive Parts, Car body sanding and polishing, DS 1220 spark trap vacuum for aluminium car body sanding, News, Success Stories, Vehicles

The RUWAC DS 1220 sparktrap vacuum is the standard vacuum for aluminium body repair work shops certified by major Car producers such as Audi, Mercedes and BMW. The RUWAC spark trap vacuums can be used for a variety of vacuum and Dedusting tasks, where sparks are present in the suction air. For every ATEX vacuum the introduction of ignition sources with the suction air must be 100 % ruled out by the user. In situations, where this is not possible the spark trap vacuum can be one of the safe …

DA1300 Mobile Industrial Vacuum + Pre-Separator/Filter

- February 6, 2018

- Success Stories, Vacuum cleaning of floors and surfaces

Thai Polyamide Co.,Ltd., Thailand used to have a local vacuum unit, which the operator stopped operating as it gave them electrocutions. During discharging the PE Pellets from Big-Bags into the conveying system, large amounts fall to the sides which needs to be manually collected. Nylon Powder is used in the printing line to keep the films from sticking to each other. After a certain amount of time, nylon powder is accumulated on the flexible dies which needs to be cleaned. Currently, they need to wait until the printing line cools …

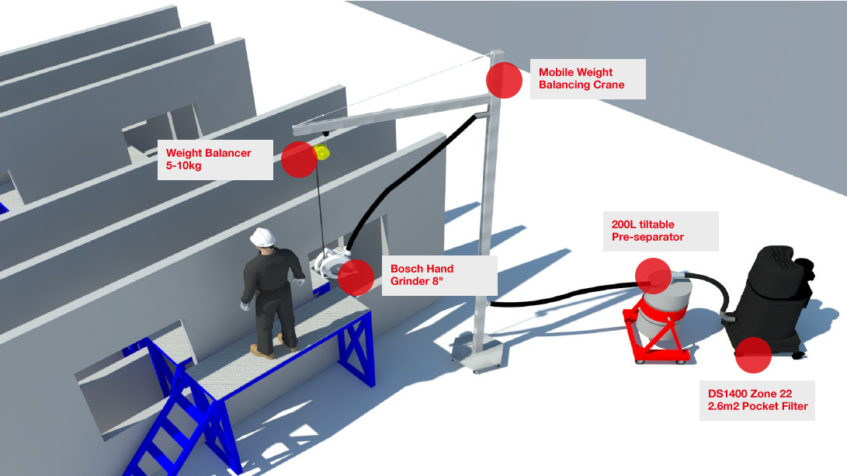

Concrete Dust Suction system for prefabricated houses production plant

- February 1, 2018

- Cement Plant, Chemical Industry, Dedusting at source, News, Success Stories

In the production of seasoning powders any different ingredients are used, all having different properties. A detailed analysis is necessary in order to provide different customizing options to solve the different dust specification challenges. Dust extraction with flexible extraction arms directly at mixer charging stations where fly dust contaminates the area. Installing a certified dust extraction system with high efficient filtration and dust collection capability. The RUWAC Dust Extractor DS 6 serves as a dust collector that can be customized for standalone operation, as a mobile extractor or as a central dust extraction system/ dust …

RUWAC DA 1220 mobile deduster.

- February 1, 2018

- Picture of the week

Long time RUWAC China customer Vision Stone Automation received another RUWAC DA 1220 mobile deduster for continuous suction of copper and iron dust from an assembly line.

Momentive Performance Materials Co.Ltd. received a DS1400 De-Centralized Vacuum System Gas-Ex Zone 1+2 on February 2015.

- February 1, 2018

- Picture of the week

Momentive Performance Materials Co.Ltd. received a DS1400 De-Centralized Vacuum System Gas-Ex Zone 1+2 on February 2015. The DS1400 Gas-Ex Zone 1+2 is combined with a 200L Pre-Filter System connected to a short Stainless Steel Piping System (25m) that leads to in total 4 suction points whereas 1 suction point can be operated at a time. The purpose of this De-Centralized Vacuum System is to vacuum very light & fine Silica Dust leaking from their production line. Mr. Attapon (Left), Production Supervisor & Mr. Pattarapol (Right) Engineering Manager says that our …