Ruwac Asia Blog

Ruwac DAV deduster for plastic trimmings from high speed IWK tube filling machine IWK (Thailand) Ltd, Thailand 2017

- March 5, 2018

- Chemical Industry, Food Industry, Mobile Vacuums, OEM, Pharmaceutical, Success Stories

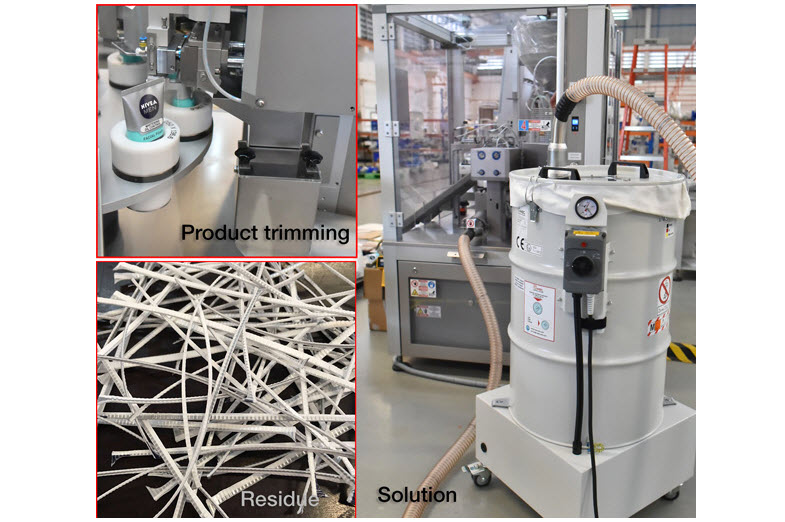

Plastic trimming pieces are evacuated much too slow from the collection chamber resulting in trimmings building lumps and clogging up the hose. This would stop the tube filler machine frequently for manual cleaning up of hose and collection chamber. Up to 10 % production time could be lost due the vacuum. Before the Ruwac solution, another de-dusting solution was implemented in which the performance & connection diameters was not carefully calculated resulting in clogged tube trimmings within the hose connections. The RUWAC DAV was tested and customized for this application. The RUWAC systems 280 mbar of vacuum and airspeed of over 40 m/sec gives no chance of clogging the hose anymore to prevent clogging of tube trimmings from IWK’s automated tube filling machine. In the high speed tube fillers of IWK , plastic trimmings are discharged to a small collection container from where they have to be vacuumed away continuously without interruption.

Industries

Pharmaceutical

Food

Chemical

Original Equipment Manufacturer

Application Category

Dedusting at source

Reason

To prevent clogging of tube trimmings from IWK’s automated tube filling machine.

In the high speed tube fillers of IWK , plastic trimmings are discharged to a small collection container from where they have to be vacuumed away continuously without interruption.

Product Group

Mobile Vacuums