Ruwac Asia Blog

NA35-D1-Typ-III DA1300 Zone 22 Wet-Separator.

- February 1, 2018

- Picture of the week

NA35-D1-Typ-III DA1300 Zone 22 Wet-Separator with Custom Suction Connection to Grinding Table. Khun Chatthaphat Siripunyanan of NHK Spring Company received the NA35-D1-Typ-III DA1300 Zone 22 Wet-Separator for Dedusting of Steel Sparks during the Grinding Process. Ruwac was selected due to detailed consultancy for the right vacuum solution and the correct performance provided specifically designed for this application.

The DA 1300 mobile vacuum with control system and piping connection for Mitsui Phenol Company in Singapore.

- February 1, 2018

- Picture of the week

Mr Anthony Teo of Mitsui Phenol Company in Singapore took possession of a DA 1300 mobile vacuum with control system and piping connection to 2 vacuum cleaning suction points at the plants packing lines. RUWAC was selected after consideration of performance, machine quality and after sales service provided by RUWAC Asia team in Singapore.

RUWAC DS 1400 ATEX Zone 22 industrial vacuums for cleaning of powder coatings.

- January 26, 2018

- Picture of the week

Mr Terry Cheng, production supervisor of Jungheinrich Lift Truck Manufacturing (Shanghai) Co.,Ltd. took possession of 2 RUWAC DS 1400 ATEX Zone 22 industrial vacuums for cleaning of powder coatings. RUWAC was chosen due to its well-known high quality and the excellent consultancy and after sales service provided by the RUWAC China team.

PGI Foods International Co.,Ltd. received a DS64000 Zone 22 Extractor System on June 2017.

- January 26, 2018

- Picture of the week

The DS64000 Extractor System with a 24m2 Cartridge Filter Class M is connected to 4 Suction Points whereas 2 suction points are operated at the same time. The purpose of this Extractor System is to extract airborne icing sugar powder from their mixer, filling station & sifting station. Khun May (Right), Production Supervisor said that our Ruwac extractor system has decreased the dust cloud within the small production area, which resulted in a healthier more productive working environment.

Saint-Gobain Abrasives (TH) Co.,Ltd. received a DS2 Wet-Separator Vacuum System.

- January 26, 2018

- Picture of the week

The DS2 Wet-Separator Vacuum System is connected to 4 Suction Points whereas 1 suction point is operated at the same time. The purpose of this Vacuum System is to de-dust grinding sparks from their QC Testing Room. Khun Darunee (Right), EHS Specialist said that our Ruwac vacuum system is essential to their operation due to compliance with ATEX regulations as well as extreme worker protection.

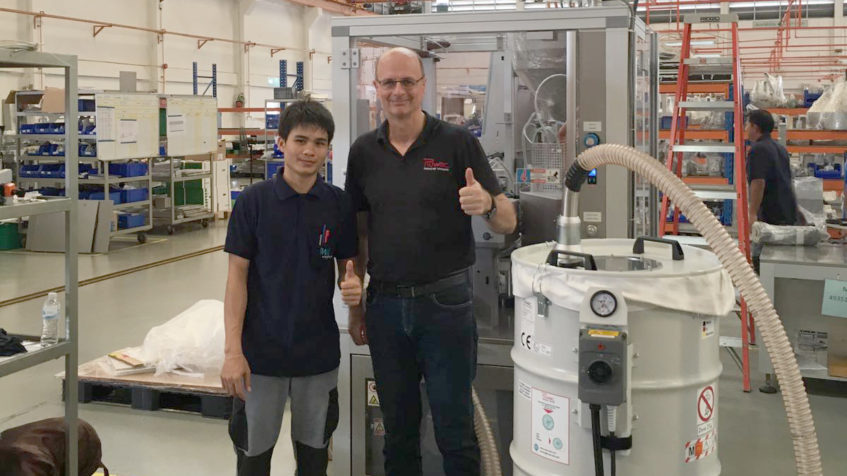

The first RUWAC DAV deduster for continuous suction of trimmings to IWK Thailand.

- January 26, 2018

- Picture of the week, Products

Mr Jens Huhn handed over the first RUWAC DAV deduster for continuous suction of trimmings to IWK Thailand. IWK is the world leading manufacturer of turn key tube filling and packing lines. The decision for RUWAC was made after extensive testing at IWK’s production plant in Thailand.

The DA1300 Dust-Ex Zone 22 is combined with a 110L Pre-separator/Filter System

- January 26, 2018

- News, Picture of the week

Whereas 2 operation modes can be switched manually by a ball valve: Cleaning of PE pellets from Big-Bag unloading station with Pre-Separator Cleaning of sticky nylon powders from Film Printing line with Pre-Filter The purpose of the DA1300 Vacuum Unit is to generally clean both areas mentioned above with 1 vacuum unit Thai Polyamide Team says that our Ruwac vacuum unit has eliminated electrocutions from cleaning due to our vacuum units’ full conductivity system & increased cleaning efficiency

Trumpf Ltd., received a NA7-11H wet-separator on 27th February 2018.

- March 15, 2017

- Picture of the week

Our OEM customer Trumpf Ltd., a manufacturer of 3D laser sintering machines, received a NA7-11H wet-separator on 27th February 2018. The purpose of this vacuum unit is to generally clean highly explosive aluminium and titanium powders from 3D laser sintering machines, which have a minimum ignition energy of lower than 1mJ. Trumpf Ltd. says that the NA7-11H is a necessary asset when cleaning their line of 3D laser sintering machines in order to comply with special regulations regarding the handling of titanium powder and other reactive powders. In this particular …