Ruwac Asia Blog

Complete Dust Control for metal work shop RUWAC Asia, Thailand 2014

- February 1, 2018

- Automotive Parts, Dedusting at source, Extraction of airborne dust, Machinery, Metal Industry, News, Steel, Success Stories, Vacuum cleaning of floors and surfaces, Vehicles

RUWAC Asia Thailand also have the contamination of the machines by metal dust and chips, which are difficult to remove manually. Practice of the air gun cleaning is very dangerous and inefficient.

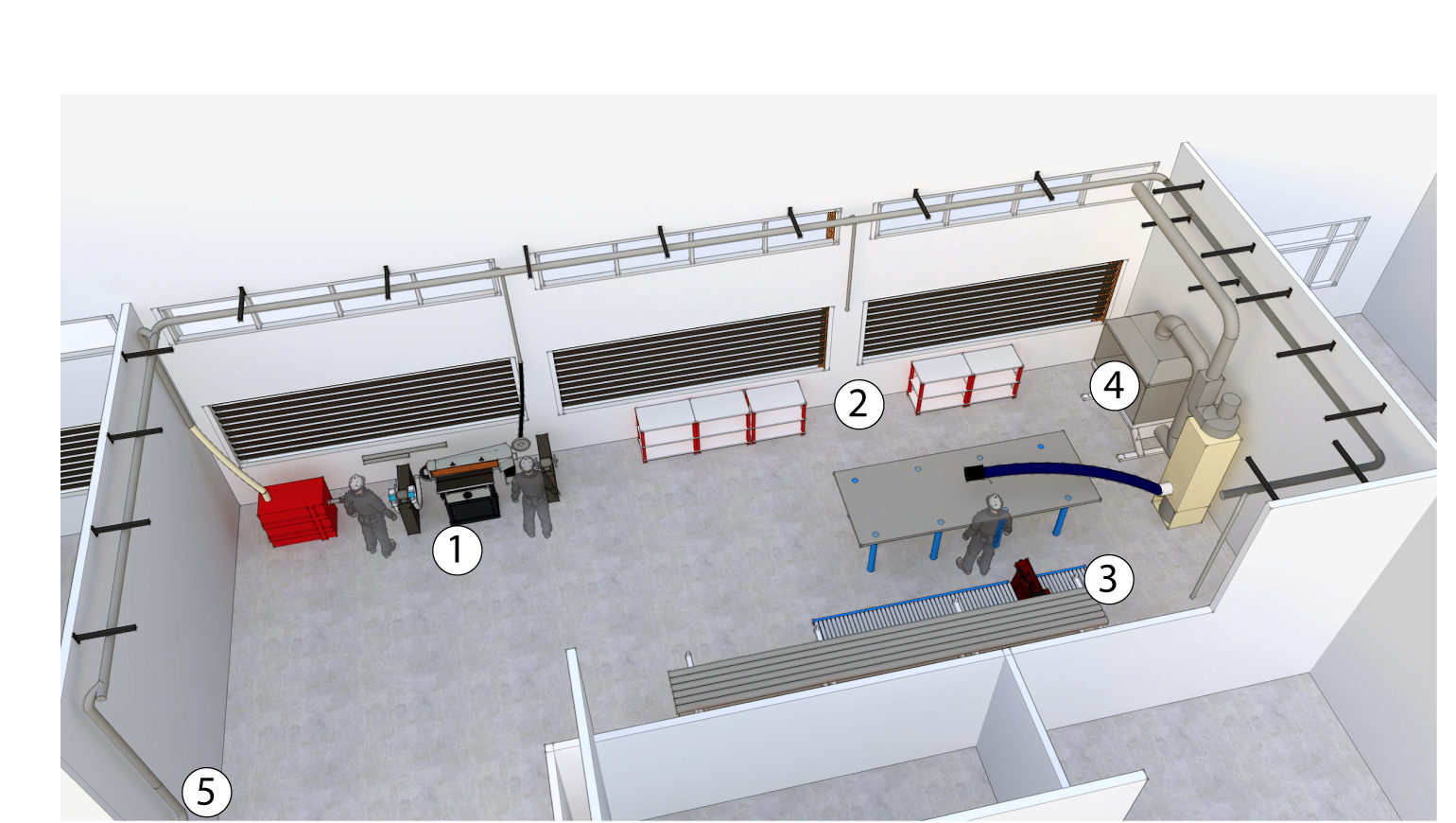

To keep the workshop and metal working machines clean without using air gun and dedusting metal sparks dust during grinding process. We are using the RUWAC Central vacuum system with NA 250 wet separator for dust and sparks. SPS 35 for mobile cleaning of metal chips and coolant. Central vacuum system with 3 end cap connection points for convenient connection of cleaning hoses.

The Advantages of this solution are:

1. Dedusting at source every time the grinder is switched on.

2. Vacuum cleaning of machines and surfaces immediately after every work step, avoiding dust deposit build up in metal working machinery.

3. Central collection of vacuumed waste in 200 l bin, which is returned to recycling contractor every 3 months. No requirement to empty dust bins manually.

When it comes to handling highly explosive materials there is no other choice than the RUWAC wet separator. Whether it is TNT, Titanium powder or air bag propellant industries worldwide rely on RUWAC know how and technology.