Ruwac Asia Blog

Centralize Vacuum in car chassis production line Honda, Malaysia 2017

- February 1, 2018

- Automotive Industry, Car body sanding and polishing, Central System, Success Stories, Vacuum cleaning of floors and surfaces

Honda, Malaysia have each operator had to work with a small standard vacuum with low capacity and small filters. The vacuum requires daily maintenance, filter changes and frequent replacement.

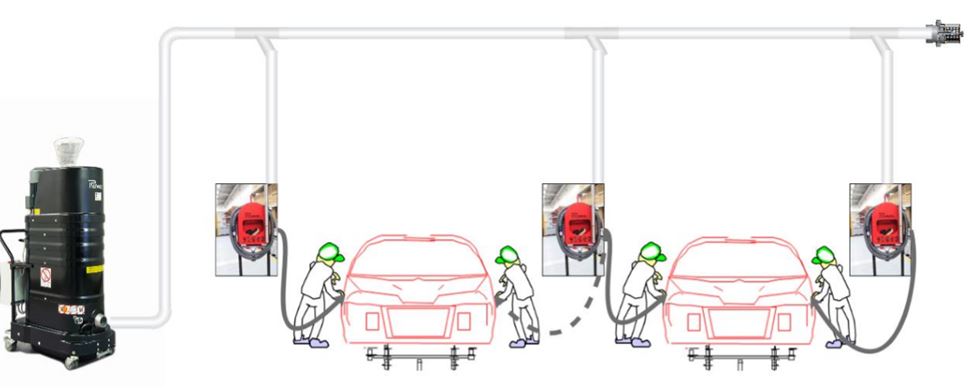

The RUWAC industrial vacuum DS 1750 with high vacuum and airvolume with automatic start/stop control and piping system for several suction points to replacing existing small standard vacuums.

Central Vacuum Systems always need very careful planning. This section can only provide examples of the most typical versions for Dedusting, Vacuum and Extraction applications with pipelines.

Application

Car body sanding and polishing

Car repair workshop cleaning

Machine cleaning

Mobile central vacuum cleaning of packing machines

Application Category

Vacuum cleaning of floors and surfaces

Reason

Before the car chassis can proceed to the painting station any dust particles must be removed.

| Task | Replacing existing small standard vacuums |

| Problem | Each operator had to work with a small standard vacuum with low capacity and small filters. The vacuum requires daily maintenance, filter changes and frequent replacement. |

| Solution | RUWAC insdustrial vacuum DS 1750 with high vacuum and airvolume. The vacuum system has automatic start/stop control and piping system for several suction points |

| Technics | Fully customized RUWAC vacuum solution. |

| Advantages | 1. Convenient central vacuum system with start/stop sensor at each operator station 2. Centrally collected metal dust 3. Large long lasting pocket filter 4. No contact of workers with filters and collected dust 5. Service contract by RUWAC Malaysia saving customers manpower |