Ruwac Asia Blog

OSHA Begins Enforcement of New Silica Dust Standards

- October 2, 2017

- Osha

On September 23rd, OSHA officially began enforcement of its revised standards for crystalline silica dust in the workplace impacting the concrete industry, with a second ruling affecting the general and maritime industries going into effect on June 23, 2018. The roll out has not been without its bumps in the road, however, and some hurdles still remain. The new ruling has brought blowback from those within the construction industry in particular who argue that these stricter guidelines are difficult to meet and train workers on in the amount of time …

Additive Manufacturing’s Evolving Nature Creates New Hurdles in Dust Safety

- September 1, 2017

- Dust Control

Additive manufacturing is one of the most rapidly growing and evolving markets happening in the industrial world right now. It’s cost-effective in terms of materials and productivity, and in many cases, it provides a greener solution that leaves less of a carbon footprint on the environment. It used to be that just those working with metals and plastics were taking advantage of this new technology, but each day, more and more industries — from food production to biomedical breakthroughs — are finding a innovative way to integrate 3D printing into …

Combustible Dust Safety Crucial Despite OSHA’s New Agenda

- August 3, 2017

- Explosion Proof, Osha

After years of delaying an analysis on combustible dust standards affecting general industry, any anticipation that safety measures would be improved came to a halt last week when the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) under President Trump abandoned any discussion of changing current regulations, citing a strain on resources and other priorities. OSHA started the rulemaking process to develop a combustible dust standard for general industry back in 2009. The Trump Administration said the changes represent “the beginning of fundamental regulatory reform and a reorientation …

Regional marketing and sales training seminar held at RUWAC Asia headquarters in Chonburi, Thailand

- July 24, 2017

- News

From 17. – 23.07.2017 Sales and marketing executives from Thailand, China and Malaysia came together for a week of intensive training and experience sharing at RUWAC Asia headquarters in Chonburi, Thailand.

RUWAC Asia at Propak Bangkok exhibition in June 2017

- June 15, 2017

- News

Once again RUWAC Asia participated in the Propak fair at Bitec exhibition center in Bangkok, Thailand. With even more customers meeting us at Propack than last year, the event was once again a huge success for the RUWAC brand in Asia.

Glass Bead Chamber Vacuum System IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Application Category, Customer, Food Industry, Glass Bead Chamber Vacuum System, Industries, OEM, Pharmaceutical, Success Stories, Thailand, Vacuum cleaning of floors and surfaces

IWK (Thailand) Limited have the issue with they material Glass Bead with high specific weight ratio which makes it very heavy. It also can be reused several times in the coating process by manually collecting glass bead material on the ground, production downtime increased as well as physical fatigue for the operator. Before the RUWAC solution, a large dust collector was implemented in which its task is to extract airborne glass bead powders from the entire chamber; the results were not sufficient and the operator had visibility & breathing issues …

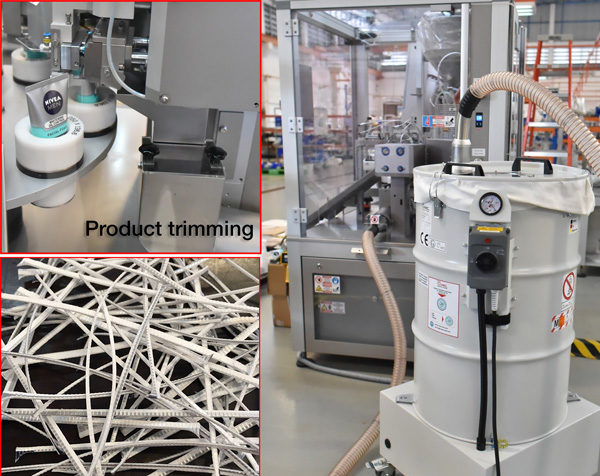

Ruwac DAV deduster for plastic trimmings from high speed IWK tube filling machine IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Chemical Industry, Continuous suction of plastic trimmings from tube filling machine , Customer, Dedusting at source, Food Industry, Industries, Mobile Vacuums, OEM, Pharmaceutical, Product Group, Ruwac DAV, Ruwac DAV connected with customer machine, Success Stories, Thailand

At IWK (Thailand) Limited the plastic trimming pieces are evacuated much too slow from the collection chamber resulting in trimmings building lumps and clogging up the hose. This would stop the tube filler machine frequently for manual cleaning up of hose and collection chamber. Up to 10 % production time could be lost due the vacuum. Before the Ruwac solution, another de-dusting solution was implemented in which the performance & connection diameters were not carefully calculated resulting in clogged tube trimmings within the hose connections. (low mbar of under 30 …

DS6 2.2 kW with total 5 suction points at Eagle Ottawa (Thailand) Co., Ltd.

- April 2, 2017

- Central System, Customer, DS6, DS6 at the customers conveyor line., Product Group, Products, Success Stories, Thailand

During the process of white leather, after the coating process the white leather has to goes through an oven to dry. But during the baking process when the leather gets dry it has got small loose leather pieces which is not falling off and sticks on to the leather. The small leather pieces will give leather at the finishing process spots on it, which is not acceptable for customers buyer. RUWAC Solution Offer: Offered DS6 2.2 kW, 20m2 Pocket Filter connect to pre-filter system and then on to a …