Ruwac Asia Blog

NA7-11H Wet-Separator Trumpf Ltd. / Mahidol University

- March 15, 2018

- Success Stories, Vacuum cleaning of floors and surfaces, Wet Separator

Our OEM customer Trumpf Ltd., a manufacturer of 3D laser sintering machines, received a NA7-11H wet-separator on 27th February 2018. The purpose of this vacuum unit is to generally clean highly explosive aluminum and titanium powders from 3D laser sintering machines, which have a minimum ignition energy of lower than 1mJ. Trumpf Ltd. says that the NA7-11H is a necessary asset when cleaning their line of 3D laser sintering machines in order to comply with special regulations regarding the handling of titanium powder and other reactive powders. In this particular order regarding …

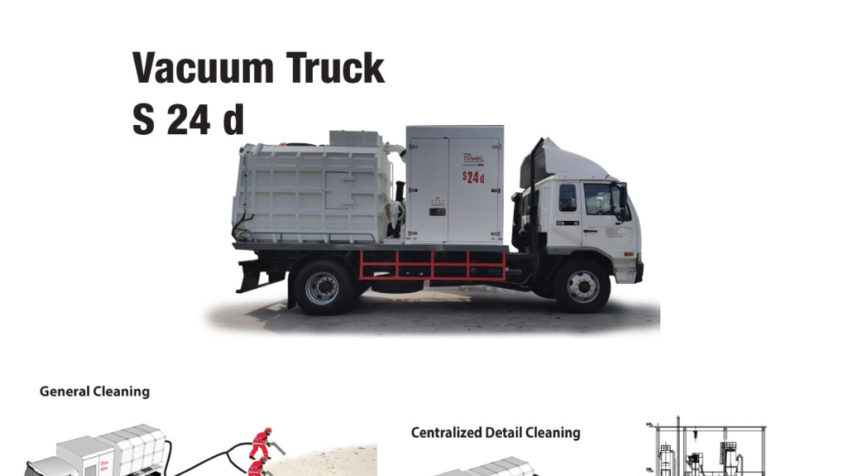

Ruwac S 24 D vacuum truck for cement and power plants CIMA, Malaysia 2017

- March 5, 2018

- Cement, Engineering, Power plant, Steel, Success Stories, Vacuum cleaning of floors and surfaces, Vacuum Truck

The RUWAC S 24 vacuum system is mounted on a Nissan 2 axle heavy duty truck with full road going permit. The vacuum system is equipped with a SIBILIA pump and its own DEUTZ Diesel engine , capable to vacuum any dry spillage material occurring in a cement plant at a capacity of up to 20 tons / h. The unit is equipped with all safety equipment as well as connectivity to a central system vacuum pipeline. RUWAC Malaysia in cooperation with DEUTZ Malaysia will take care for continuous operator training …

DA1300 Mobile Industrial Vacuum + Pre-Separator/Filter Thai Polyamide Co.,Ltd., Thailand 2017

- March 5, 2018

- Success Stories, Vacuum cleaning of floors and surfaces

The DA1300 Dust-Ex Zone 22 is combined with a 110L Pre-separator/Filter System whereas 2 operation modes can be switched manually by a ball valve: Cleaning of PE pellets from Big-Bag unloading station with Pre-Separator Cleaning of sticky nylon powders from Film Printing line with Pre-Filter The purpose of the DA1300 Vacuum Unit is to generally clean both areas mentioned above with 1 vacuum unit. Thai Polyamide Team says that our Ruwac vacuum unit has eliminated electrocutions from cleaning due to our vacuum units’ full conductivity system & increased cleaning efficiency. …

Ruwac DLS1221 removes fine dust and aluminum chips inside our automotive part product Bosch Automotive Steering Nanjing, China 2017

- March 5, 2018

- Aerospace Industry, Automotive Parts, Electronics, Engineering, Machine cleaning, Metal Industry, OEM, Ruwac DLS1221 removes fine dust and aluminum chips, Steel, Success Stories, Vacuum cleaning of floors and surfaces

The RUWAC compressed air drive vacuum produces up to 300 mbar vacuum and can tolerate unlimited start/stops per hour as was required by the customer. RUWAC produced a special cleaning nozzle to fit exactly for this application. The smaller the cleaning nozzle diameter the more mbar performance is required. Existing small vacuums could hat much too low mbar and airvolume to be able to vacuum small dust away. Our compressed-air model offers impressive performance for all periods of use. It is extremely maneuverable and complies with all safety requirements for vacuuming all …

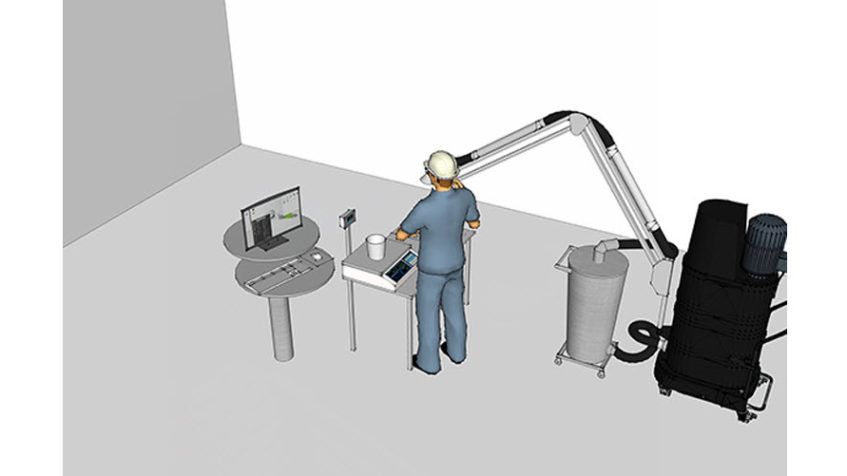

Dust extraction and vacuum cleaning in powder charging area AZO, Thailand 2016

- March 5, 2018

- Chemical Industry, Extraction of airborne dust, Food Industry, OEM, Packaging, Paint, Pharmaceutical, Plastic, Rubber, Success Stories, Vacuum cleaning of floors and surfaces

Many different types of powders and fly dust some with sticky and hygroscopic properties. AZO, Thailand was looking for a compact but powerful machine to extract fly dust during manual powder charging of mixers and other production machines. The same machine should be able to be used for vacuum cleaning around the charging area and dust class requirement is H and clean room. The DS 1400 RUWAC mobile vacuum with 2.6 m2 filter , extraction arm , cleaning accessories and prefilter High airvolume suitable for small dust extraction task as well …

DS1750 Sludge Vacuum System 7.5kW Turbine Drive IRPC (Public) Co.,Ltd., Thailand 2017

- March 5, 2018

- DS1750 Sludge Vacuum System, Electronics, Engineering, Foundry, Machinery, Plastic, Power plant, Success Stories, Vacuum cleaning of floors and surfaces

IRPC operators used to clean this area by manually scooping up the heavy sludge on a monthly basis, which is a time consuming & physically demanding task to do the general Cleaning of waste polyethylene sludge with chemical liquids, oils & water. A DS1750 Sludge Vacuum with full automatic features has been implemented to clean sludge from 4x waste water pits on a weekly basis to reduce physical demand during cleaning task and safe time by reduce manpower from 5 operators to 2 operators. DS1750 7.5kW Turbine Drive, 2x 5m2 Oil …

DS1750 Silo Vacuum System Siam Kubota Metal Technology Co.,Ltd. Thailand 2017

- March 5, 2018

- Steel, Success Stories, Vacuum cleaning of floors and surfaces

Our customer Siam Kubota Metal Technology Co.,Ltd., Thailand have many steel shots by its nature have a very high specific weight making the material very heavy. By manually shoveling these steel shots, operator’s physical health is & operation downtime is effected. To reduce operation down time of collecting steel shots but Increase collection capacity to time ratio and also convenient discharge through bottom discharge valve into customer containers. The DS1750 Silo Vacuum System 7.5kW Turbine Drive, 4.5m2 Pocket Filter Class M, 160L Silo Container, manual heavy-duty bottom discharge valve is …

DA1300 Mobile Industrial Vacuum + Pre-Separator/Filter

- February 6, 2018

- Success Stories, Vacuum cleaning of floors and surfaces

Thai Polyamide Co.,Ltd., Thailand used to have a local vacuum unit, which the operator stopped operating as it gave them electrocutions. During discharging the PE Pellets from Big-Bags into the conveying system, large amounts fall to the sides which needs to be manually collected. Nylon Powder is used in the printing line to keep the films from sticking to each other. After a certain amount of time, nylon powder is accumulated on the flexible dies which needs to be cleaned. Currently, they need to wait until the printing line cools …