Ruwac Asia Blog

Glass Bead Chamber Vacuum System IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Application Category, Customer, Food Industry, Glass Bead Chamber Vacuum System, Industries, OEM, Pharmaceutical, Success Stories, Thailand, Vacuum cleaning of floors and surfaces

IWK (Thailand) Limited have the issue with they material Glass Bead with high specific weight ratio which makes it very heavy. It also can be reused several times in the coating process by manually collecting glass bead material on the ground, production downtime increased as well as physical fatigue for the operator. Before the RUWAC solution, a large dust collector was implemented in which its task is to extract airborne glass bead powders from the entire chamber; the results were not sufficient and the operator had visibility & breathing issues …

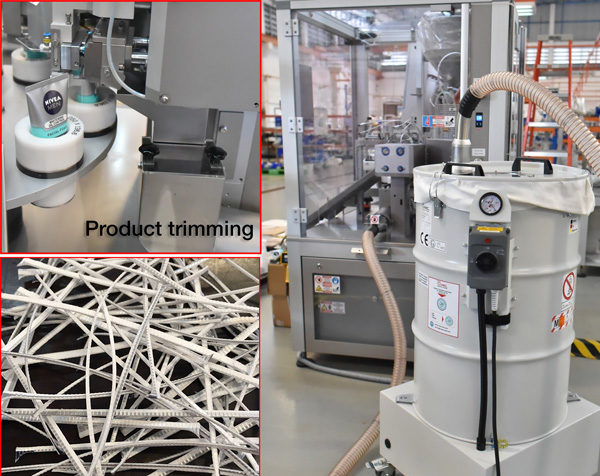

Ruwac DAV deduster for plastic trimmings from high speed IWK tube filling machine IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Chemical Industry, Continuous suction of plastic trimmings from tube filling machine , Customer, Dedusting at source, Food Industry, Industries, Mobile Vacuums, OEM, Pharmaceutical, Product Group, Ruwac DAV, Ruwac DAV connected with customer machine, Success Stories, Thailand

At IWK (Thailand) Limited the plastic trimming pieces are evacuated much too slow from the collection chamber resulting in trimmings building lumps and clogging up the hose. This would stop the tube filler machine frequently for manual cleaning up of hose and collection chamber. Up to 10 % production time could be lost due the vacuum. Before the Ruwac solution, another de-dusting solution was implemented in which the performance & connection diameters were not carefully calculated resulting in clogged tube trimmings within the hose connections. (low mbar of under 30 …

Aerospace

- March 9, 2017

- Aerospace Industry, Industries

Aplication Machine cleaning Suction from hand sander Aluminium car body sanding with sparktrap Cleaning titanium powder from laser metal sintering process Wet separation of explosive and reactive dust Aplication Packages PowerVac Success Stories Complete Dust Control for metal work shop Wet seperatoRuwac DLS1221 removes fine dust and aluminum chips inside our automotive part productr vacuum for highly explosive Titanium additives Suction Media Aluminium dust Titanium Powder for 3 D laser Carbon fine dust Reference

Additive

- March 7, 2016

- Additive manufacturing, Industries

Aplication Machine cleaning Vacuum cleaning of powder processing machines Success Stories Safe vacuum cleaning in Additive Manufacturing Wet seperator vacuum for highly explosive Titanium additives Suction Media Aluminium dust Titanium Powder for 3 D laser Alumnium additive for 3 D Laser Application Packages Safe vacuum cleaning in Additive Manufacturing Wet seperator vacuum for highly explosive Titanium additives Reference

RUWAC / PUTZMAUS tube cleaning system for biomass boiler at Thai Asahi, Thailand 2016

- April 8, 2014

- Application Packages, Boiler cleaning, Boiler Cleaning, Foundry, Machinery, Metal Industry, OEM, ProPak Thailand, Putzmaus Boiler Cleaning, Success Stories, Thailand, Vacuum cleaning of floors and surfaces

Thai Asahi, Thailand has the problem with the old biomass boiler cleaning pole which has consume lots of time and man power for the cleaning process of the boiler. Two men power and one-hole day they have needed to clean the boiler. The PUTZMAUS boiler cleaning solution integrated with the RUWAC direct suction system makes regular cleaning of any kind of boiler tubes easy, efficient and environmental friendly. All residues are pushed to the front end of the tube by PUTZMAUS and are vacuumed into a pre-separation bin by …

Vehicles

- March 14, 2014

- Industries, Vehicles

Success Stories Centralize Vacuum in car chassis production line Complete Dust Control for metal work shop DS 1220 spark trap vacuum for aluminium car body sanding Suction Media Application Packages PowerVac Reference

Textile

- March 14, 2014

- Industries, Textile

Success Stories RUWAC / PUTZMAUS tube cleaning system for biomass boiler Complete Dust Control for metal work shop Concrete Dust Suction system for prefabricated houses production plant Suction Media Application Packages RUWAC / PUTZMAUS tube cleaning system for biomass boiler Reference

Steel

- March 14, 2014

- Industries, Steel

Success Stories RUWAC / PUTZMAUS tube cleaning system for biomass boiler Complete Dust Control for metal work shop Concrete Dust Suction system for prefabricated houses production plant Suction Media Application Packages RUWAC / PUTZMAUS tube cleaning system for biomass boiler Reference