Ruwac Asia Blog

DS1750 Silo Vacuum System Siam Kubota Metal Technology Co.,Ltd. Thailand 2017

- March 5, 2018

- Steel, Success Stories, Vacuum cleaning of floors and surfaces

Our customer Siam Kubota Metal Technology Co.,Ltd., Thailand have many steel shots by its nature have a very high specific weight making the material very heavy. By manually shoveling these steel shots, operator’s physical health is & operation downtime is effected. To reduce operation down time of collecting steel shots but Increase collection capacity to time ratio and also convenient discharge through bottom discharge valve into customer containers. The DS1750 Silo Vacuum System 7.5kW Turbine Drive, 4.5m2 Pocket Filter Class M, 160L Silo Container, manual heavy-duty bottom discharge valve is …

DA1300 Mobile Industrial Vacuum + Pre-Separator/Filter

- February 6, 2018

- Success Stories, Vacuum cleaning of floors and surfaces

Thai Polyamide Co.,Ltd., Thailand used to have a local vacuum unit, which the operator stopped operating as it gave them electrocutions. During discharging the PE Pellets from Big-Bags into the conveying system, large amounts fall to the sides which needs to be manually collected. Nylon Powder is used in the printing line to keep the films from sticking to each other. After a certain amount of time, nylon powder is accumulated on the flexible dies which needs to be cleaned. Currently, they need to wait until the printing line cools …

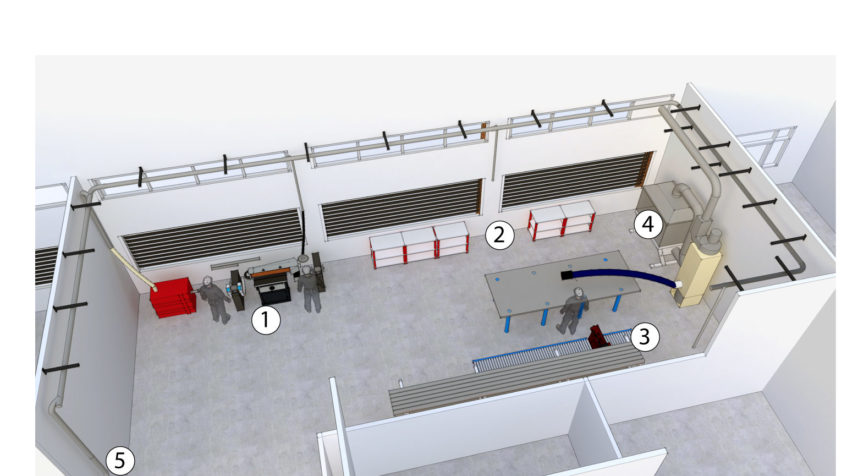

Concrete Dust Suction system for prefabricated houses production plant

- February 1, 2018

- Cement Plant, Chemical Industry, Dedusting at source, News, Success Stories

In the production of seasoning powders any different ingredients are used, all having different properties. A detailed analysis is necessary in order to provide different customizing options to solve the different dust specification challenges. Dust extraction with flexible extraction arms directly at mixer charging stations where fly dust contaminates the area. Installing a certified dust extraction system with high efficient filtration and dust collection capability. The RUWAC Dust Extractor DS 6 serves as a dust collector that can be customized for standalone operation, as a mobile extractor or as a central dust extraction system/ dust …

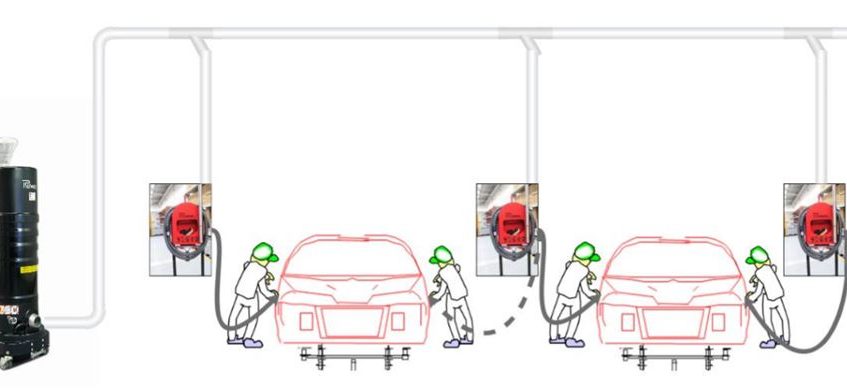

Centralize Vacuum in car chassis production line Honda, Malaysia 2017

- February 1, 2018

- Automotive Industry, Car body sanding and polishing, Central System, Success Stories, Vacuum cleaning of floors and surfaces

Honda, Malaysia have each operator had to work with a small standard vacuum with low capacity and small filters. The vacuum requires daily maintenance, filter changes and frequent replacement. The RUWAC industrial vacuum DS 1750 with high vacuum and airvolume with automatic start/stop control and piping system for several suction points to replacing existing small standard vacuums. Central Vacuum Systems always need very careful planning. This section can only provide examples of the most typical versions for Dedusting, Vacuum and Extraction applications with pipelines. Industries Automotive Parts Aerospace Industry Vehicles Application …

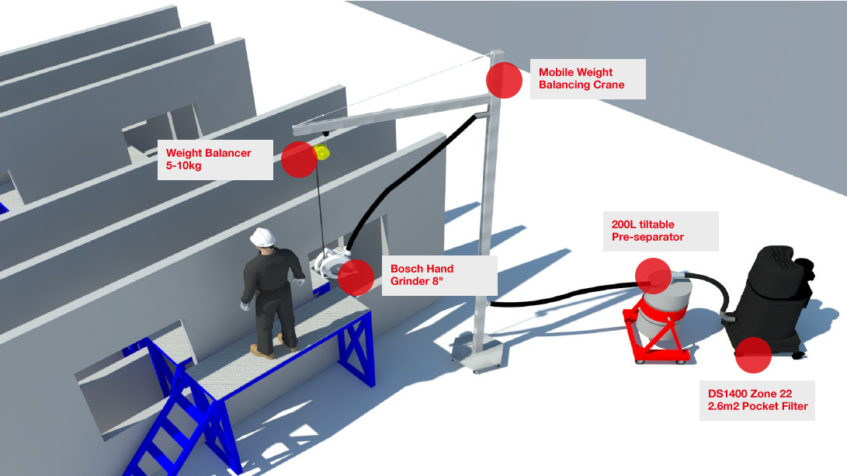

Complete Dust Control for metal work shop RUWAC Asia, Thailand 2014

- February 1, 2018

- Automotive Parts, Dedusting at source, Extraction of airborne dust, Machinery, Metal Industry, News, Steel, Success Stories, Vacuum cleaning of floors and surfaces, Vehicles

RUWAC Asia Thailand also have the contamination of the machines by metal dust and chips, which are difficult to remove manually. Practice of the air gun cleaning is very dangerous and inefficient. To keep the workshop and metal working machines clean without using air gun and dedusting metal sparks dust during grinding process. We are using the RUWAC Central vacuum system with NA 250 wet separator for dust and sparks. SPS 35 for mobile cleaning of metal chips and coolant. Central vacuum system with 3 end cap connection points for …

Glass Bead Chamber Vacuum System IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Application Category, Customer, Food Industry, Glass Bead Chamber Vacuum System, Industries, OEM, Pharmaceutical, Success Stories, Thailand, Vacuum cleaning of floors and surfaces

IWK (Thailand) Limited have the issue with they material Glass Bead with high specific weight ratio which makes it very heavy. It also can be reused several times in the coating process by manually collecting glass bead material on the ground, production downtime increased as well as physical fatigue for the operator. Before the RUWAC solution, a large dust collector was implemented in which its task is to extract airborne glass bead powders from the entire chamber; the results were not sufficient and the operator had visibility & breathing issues …

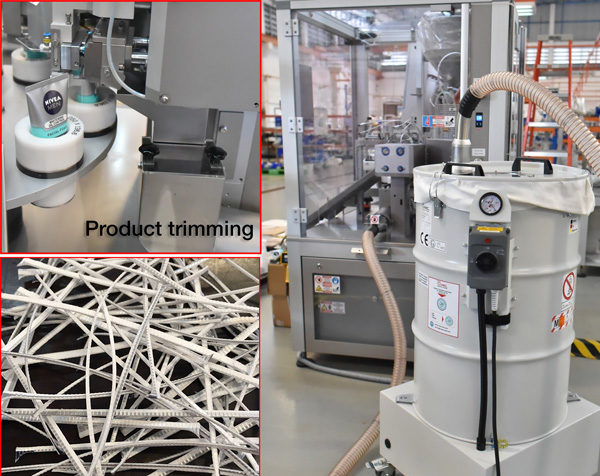

Ruwac DAV deduster for plastic trimmings from high speed IWK tube filling machine IWK (Thailand) Ltd, Thailand 2017

- April 8, 2017

- Chemical Industry, Continuous suction of plastic trimmings from tube filling machine , Customer, Dedusting at source, Food Industry, Industries, Mobile Vacuums, OEM, Pharmaceutical, Product Group, Ruwac DAV, Ruwac DAV connected with customer machine, Success Stories, Thailand

At IWK (Thailand) Limited the plastic trimming pieces are evacuated much too slow from the collection chamber resulting in trimmings building lumps and clogging up the hose. This would stop the tube filler machine frequently for manual cleaning up of hose and collection chamber. Up to 10 % production time could be lost due the vacuum. Before the Ruwac solution, another de-dusting solution was implemented in which the performance & connection diameters were not carefully calculated resulting in clogged tube trimmings within the hose connections. (low mbar of under 30 …

Extraction and De-Dusting of coffee creamer at Korn Thai Co., Ltd.

- April 8, 2014

- Dedusting at source, Extraction and De-Dusting of coffee creamer, Extraction of airborne dust

Customer Name: Korn Thai Co., Ltd. Application: Extraction and De-Dusting of coffee creamer. Solution Extraction protection of operator Customers issue: During the filling process of coffee creamer powder into 5-20kg bags, every single bag has to filled manually by hand. The coffee mate dust is present during the filling process, the impact of the powder when the bag is almost full the coffee mate powder gets airborne, causes that the operator has to breath the airborne creamer dust in and protects himself only with a simple dust mask. …